Smart shelf technology transforms retail by providing real-time inventory tracking and customer behavior insights, enhancing stock accuracy and shopper experience. Warehouse robotics optimize logistics with automated picking, packing, and transportation, significantly improving operational efficiency and reducing labor costs. Explore how integrating these technologies can revolutionize retail supply chains and boost profitability.

Why it is important

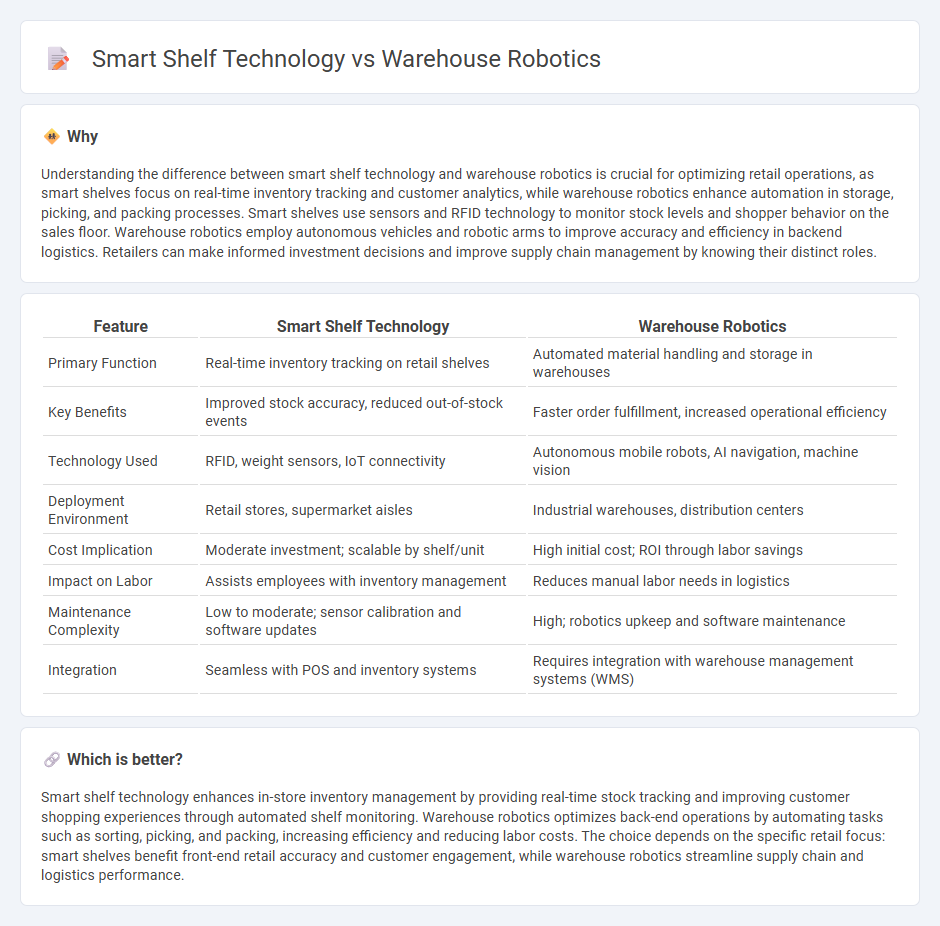

Understanding the difference between smart shelf technology and warehouse robotics is crucial for optimizing retail operations, as smart shelves focus on real-time inventory tracking and customer analytics, while warehouse robotics enhance automation in storage, picking, and packing processes. Smart shelves use sensors and RFID technology to monitor stock levels and shopper behavior on the sales floor. Warehouse robotics employ autonomous vehicles and robotic arms to improve accuracy and efficiency in backend logistics. Retailers can make informed investment decisions and improve supply chain management by knowing their distinct roles.

Comparison Table

| Feature | Smart Shelf Technology | Warehouse Robotics |

|---|---|---|

| Primary Function | Real-time inventory tracking on retail shelves | Automated material handling and storage in warehouses |

| Key Benefits | Improved stock accuracy, reduced out-of-stock events | Faster order fulfillment, increased operational efficiency |

| Technology Used | RFID, weight sensors, IoT connectivity | Autonomous mobile robots, AI navigation, machine vision |

| Deployment Environment | Retail stores, supermarket aisles | Industrial warehouses, distribution centers |

| Cost Implication | Moderate investment; scalable by shelf/unit | High initial cost; ROI through labor savings |

| Impact on Labor | Assists employees with inventory management | Reduces manual labor needs in logistics |

| Maintenance Complexity | Low to moderate; sensor calibration and software updates | High; robotics upkeep and software maintenance |

| Integration | Seamless with POS and inventory systems | Requires integration with warehouse management systems (WMS) |

Which is better?

Smart shelf technology enhances in-store inventory management by providing real-time stock tracking and improving customer shopping experiences through automated shelf monitoring. Warehouse robotics optimizes back-end operations by automating tasks such as sorting, picking, and packing, increasing efficiency and reducing labor costs. The choice depends on the specific retail focus: smart shelves benefit front-end retail accuracy and customer engagement, while warehouse robotics streamline supply chain and logistics performance.

Connection

Smart shelf technology and warehouse robotics are interconnected through real-time inventory management and automated stock replenishment. Smart shelves use sensors and RFID to monitor product levels, triggering warehouse robots to retrieve or restock items efficiently. This integration enhances accuracy, reduces labor costs, and optimizes supply chain workflows in retail operations.

Key Terms

Automation

Warehouse robotics enhance automation by utilizing autonomous mobile robots (AMRs) and robotic arms to streamline inventory movement and order fulfillment, reducing labor costs and errors. Smart shelf technology integrates IoT sensors and RFID tags to provide real-time inventory tracking and automatic restocking alerts, improving accuracy and supply chain efficiency. Explore how these innovative automation solutions transform warehouse operations for increased productivity and cost savings.

Inventory management

Warehouse robotics streamline inventory management by automating tasks such as picking, sorting, and transporting goods, increasing accuracy and reducing labor costs. Smart shelf technology enhances real-time inventory tracking through sensor integration and RFID tagging, providing instant data on stock levels and product movement. Explore how these innovations transform inventory management for improved efficiency and accuracy.

Real-time data

Warehouse robotics and smart shelf technology both enhance operational efficiency through real-time data integration, enabling precise inventory tracking and dynamic stock management. Warehouse robotics uses sensors and automated systems to monitor and adjust inventory levels continuously, while smart shelves employ weight sensors and RFID tags to provide instant updates on product availability and movement. Explore further to understand how these technologies transform supply chain visibility and decision-making.

Source and External Links

Overview of Warehouse Robotics - Exotec - Warehouse robotics uses automated systems like AGVs, AMRs, ASRS, and robotic arms to perform tasks such as picking, packing, sorting, and transporting goods, improving efficiency, accuracy, and scalability in warehouses.

15 Types of Warehouse Robotics For Optimal Efficiency - Modula USA - Warehouse robotics best practices include evaluating tasks for automation, integrating robots with warehouse management systems to optimize inventory accuracy and space use, and training staff to operate robotic equipment effectively.

What Is Warehouse Robotics? The Ultimate Guide for 2025 - NetSuite - Warehouse robots excel in specialized tasks such as picking, sorting, loading/unloading, palletizing, packaging, transportation, delivery, and replenishment by leveraging AI, computer vision, and autonomous navigation for faster and error-reduced operations.

dowidth.com

dowidth.com