Assortment planning focuses on selecting the right mix of products to meet customer demand and maximize sales, while stock replenishment ensures timely restocking of inventory to prevent stockouts and maintain optimal stock levels. Effective coordination between assortment planning and stock replenishment enhances customer satisfaction and operational efficiency in retail stores. Explore deeper insights into how these processes drive retail success and profitability.

Why it is important

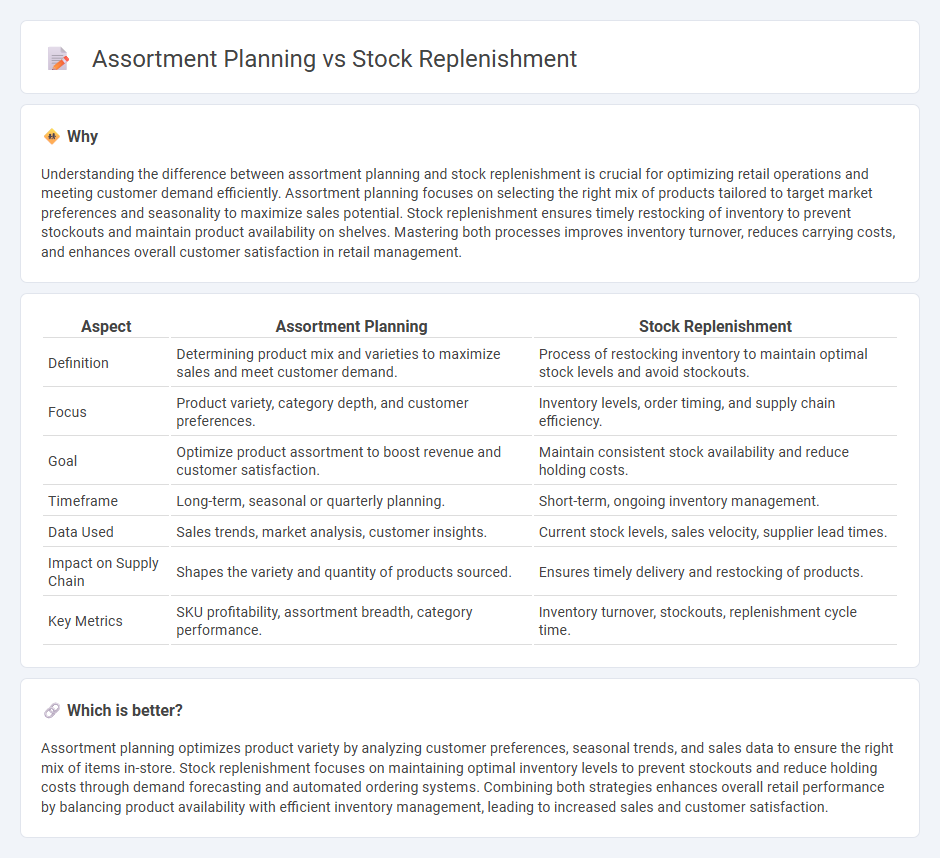

Understanding the difference between assortment planning and stock replenishment is crucial for optimizing retail operations and meeting customer demand efficiently. Assortment planning focuses on selecting the right mix of products tailored to target market preferences and seasonality to maximize sales potential. Stock replenishment ensures timely restocking of inventory to prevent stockouts and maintain product availability on shelves. Mastering both processes improves inventory turnover, reduces carrying costs, and enhances overall customer satisfaction in retail management.

Comparison Table

| Aspect | Assortment Planning | Stock Replenishment |

|---|---|---|

| Definition | Determining product mix and varieties to maximize sales and meet customer demand. | Process of restocking inventory to maintain optimal stock levels and avoid stockouts. |

| Focus | Product variety, category depth, and customer preferences. | Inventory levels, order timing, and supply chain efficiency. |

| Goal | Optimize product assortment to boost revenue and customer satisfaction. | Maintain consistent stock availability and reduce holding costs. |

| Timeframe | Long-term, seasonal or quarterly planning. | Short-term, ongoing inventory management. |

| Data Used | Sales trends, market analysis, customer insights. | Current stock levels, sales velocity, supplier lead times. |

| Impact on Supply Chain | Shapes the variety and quantity of products sourced. | Ensures timely delivery and restocking of products. |

| Key Metrics | SKU profitability, assortment breadth, category performance. | Inventory turnover, stockouts, replenishment cycle time. |

Which is better?

Assortment planning optimizes product variety by analyzing customer preferences, seasonal trends, and sales data to ensure the right mix of items in-store. Stock replenishment focuses on maintaining optimal inventory levels to prevent stockouts and reduce holding costs through demand forecasting and automated ordering systems. Combining both strategies enhances overall retail performance by balancing product availability with efficient inventory management, leading to increased sales and customer satisfaction.

Connection

Assortment planning directly influences stock replenishment by determining the optimal product mix based on customer demand and sales forecasts. Accurate assortment planning ensures that replenishment cycles align with inventory turnover rates, minimizing stockouts and overstock situations. Integrating these processes enhances inventory efficiency, reduces holding costs, and boosts overall retail profitability.

Key Terms

Inventory Turnover

Stock replenishment ensures timely restocking of products to maintain optimal inventory levels and prevent stockouts, directly impacting inventory turnover by reducing holding costs. Assortment planning strategically selects product variety and quantity to match customer demand trends, enhancing sales velocity and improving inventory turnover rates. Explore further to optimize your inventory strategies and boost turnover performance.

SKU Rationalization

Stock replenishment ensures optimal inventory levels by automatically restocking SKUs based on real-time sales data and demand forecasts, minimizing stockouts and overstocks. Assortment planning focuses on selecting the right mix of SKUs to maximize sales and profitability, leveraging SKU rationalization to eliminate underperforming products and streamline the product portfolio. Explore how balancing stock replenishment with strategic assortment planning can enhance your SKU rationalization process and boost overall inventory efficiency.

Demand Forecasting

Stock replenishment leverages demand forecasting to maintain optimal inventory levels, minimizing stockouts and overstock situations by analyzing historical sales data and market trends. Assortment planning uses demand forecasts to determine the ideal product mix tailored to customer preferences and location-specific demands, maximizing sales potential and customer satisfaction. Explore more about integrating demand forecasting to enhance inventory strategies effectively.

Source and External Links

Stock Replenishment Methods: How to Replenish Inventory - Shopify - Stock replenishment involves monitoring inventory levels, forecasting demand, setting reorder points, creating and processing purchase orders, receiving new stock, and updating inventory to maintain an optimal stock level and avoid overstock or stockouts.

What Is Stock Replenishment? | NetSuite - Stock replenishment is the process of moving inventory at an optimal rate to meet customer demand, balancing inventory holding costs, and deciding how much and when to reorder based on demand forecasting and storage considerations.

Stock Replenishment: What It Is and Strategies For Success - Stock replenishment ensures the right stock is in the right place at the right time to meet demand, using methods like push (forecast-driven) and pull systems to avoid stockouts, minimize overstock, and reduce costs.

dowidth.com

dowidth.com