Loss prevention analytics focuses on identifying and mitigating theft, fraud, and operational inefficiencies through data-driven insights, utilizing transaction monitoring, video surveillance, and employee behavior analysis. Predictive inventory loss modeling leverages historical data and machine learning algorithms to forecast potential inventory shrinkage, optimize stock levels, and reduce out-of-stock situations. Explore the latest techniques and tools shaping efficient retail loss management by learning more about these advanced solutions.

Why it is important

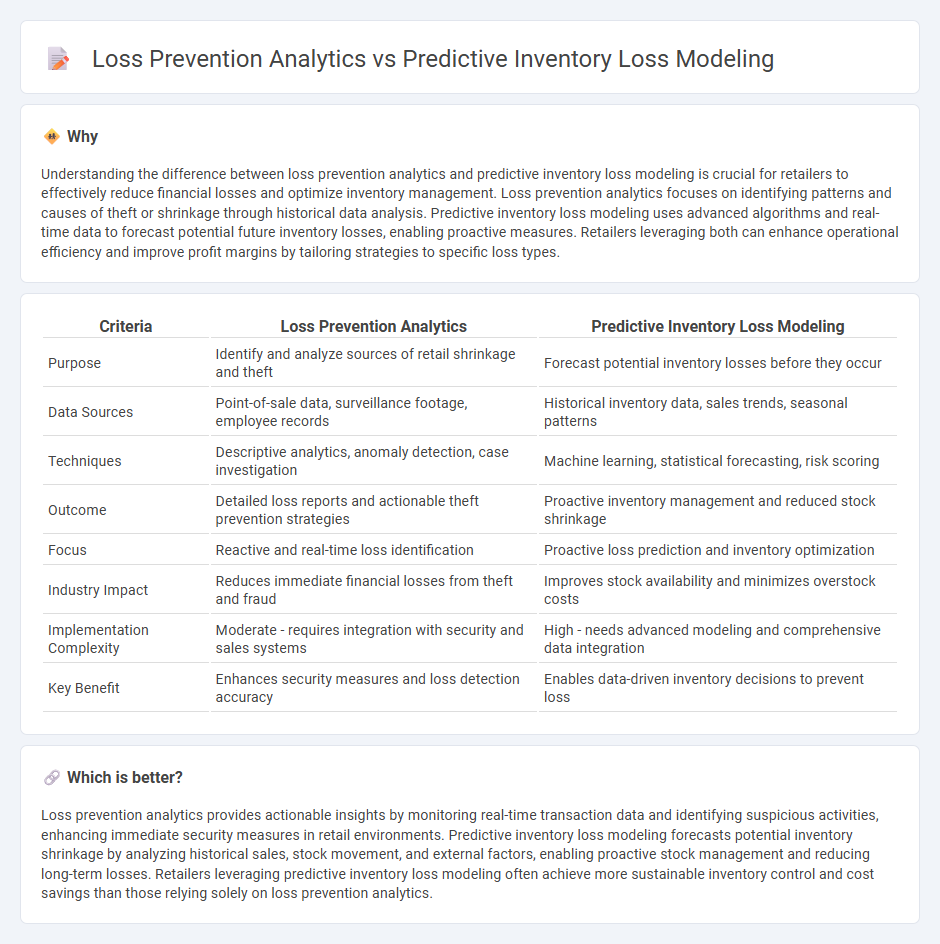

Understanding the difference between loss prevention analytics and predictive inventory loss modeling is crucial for retailers to effectively reduce financial losses and optimize inventory management. Loss prevention analytics focuses on identifying patterns and causes of theft or shrinkage through historical data analysis. Predictive inventory loss modeling uses advanced algorithms and real-time data to forecast potential future inventory losses, enabling proactive measures. Retailers leveraging both can enhance operational efficiency and improve profit margins by tailoring strategies to specific loss types.

Comparison Table

| Criteria | Loss Prevention Analytics | Predictive Inventory Loss Modeling |

|---|---|---|

| Purpose | Identify and analyze sources of retail shrinkage and theft | Forecast potential inventory losses before they occur |

| Data Sources | Point-of-sale data, surveillance footage, employee records | Historical inventory data, sales trends, seasonal patterns |

| Techniques | Descriptive analytics, anomaly detection, case investigation | Machine learning, statistical forecasting, risk scoring |

| Outcome | Detailed loss reports and actionable theft prevention strategies | Proactive inventory management and reduced stock shrinkage |

| Focus | Reactive and real-time loss identification | Proactive loss prediction and inventory optimization |

| Industry Impact | Reduces immediate financial losses from theft and fraud | Improves stock availability and minimizes overstock costs |

| Implementation Complexity | Moderate - requires integration with security and sales systems | High - needs advanced modeling and comprehensive data integration |

| Key Benefit | Enhances security measures and loss detection accuracy | Enables data-driven inventory decisions to prevent loss |

Which is better?

Loss prevention analytics provides actionable insights by monitoring real-time transaction data and identifying suspicious activities, enhancing immediate security measures in retail environments. Predictive inventory loss modeling forecasts potential inventory shrinkage by analyzing historical sales, stock movement, and external factors, enabling proactive stock management and reducing long-term losses. Retailers leveraging predictive inventory loss modeling often achieve more sustainable inventory control and cost savings than those relying solely on loss prevention analytics.

Connection

Loss prevention analytics leverages data to identify patterns of theft, fraud, and operational inefficiencies in retail environments, enabling targeted interventions. Predictive inventory loss modeling uses these insights alongside historical sales and shrinkage data to forecast potential inventory losses, informing proactive stocking and security measures. Integrating both approaches enhances accuracy in loss detection, optimizing inventory control and reducing financial impact.

Key Terms

Predictive Inventory Loss Modeling:

Predictive Inventory Loss Modeling leverages advanced machine learning algorithms and historical sales data to identify patterns and forecast potential inventory shrinkage more accurately than traditional loss prevention analytics. This approach incorporates real-time data from point-of-sale systems, supply chain logistics, and employee activity to create dynamic risk profiles for different product categories. Discover how predictive inventory loss modeling enhances operational efficiency and reduces shrinkage by exploring detailed case studies and implementation strategies.

Shrinkage Forecasting

Predictive inventory loss modeling leverages machine learning algorithms and historical data to forecast shrinkage trends, enabling proactive adjustments in stock management. Loss prevention analytics uses real-time data and behavioral insights to identify anomalies and prevent theft or operational inefficiencies that contribute to shrinkage. Explore detailed methodologies and technologies shaping effective shrinkage forecasting strategies.

Machine Learning Algorithms

Predictive inventory loss modeling leverages advanced machine learning algorithms like random forests, neural networks, and gradient boosting to forecast potential inventory shrinkage by analyzing historical sales, inventory levels, and loss patterns. Loss prevention analytics utilizes similar algorithms but emphasizes real-time anomaly detection and transaction monitoring to identify fraudulent behavior and operational inefficiencies. Explore more to understand how these machine learning techniques transform retail loss management strategies.

Source and External Links

A Comprehensive Guide to Predictive Inventory Planning and Management - Predictive inventory loss modeling involves using large data sets such as historical demand, industry benchmarks, and supply chain data to forecast risks and optimize inventory, automating the planning process to handle complex facility-specific constraints and real-time variables like weather or trends for more accurate predictions.

5 Ways Predictive Inventory Management Prevents Overstock and Stockouts - This approach uses AI and machine learning to anticipate inventory demand by analyzing factors such as sales trends, real-time consumption, seasonal changes, supplier reliability, and external influences like weather and geopolitical events to model scenarios that prevent losses due to overstock or stockout situations.

Predictive Inventory Management to End Stockouts and Overstocks - Predictive inventory modeling employs statistical algorithms fed by diverse data inputs including sales history and market trends to generate scientifically accurate forecasts that reduce inventory loss by balancing costs, improving customer satisfaction, and informing strategic inventory decisions.

dowidth.com

dowidth.com