Phantom inventory occurs when stock levels show items as available despite them being physically absent, often due to scanning errors or theft, leading to inaccurate inventory management. Backorder refers to customer orders placed for out-of-stock products, requiring fulfillment once the inventory is replenished to avoid lost sales and delays. Explore deeper insights into managing phantom inventory and backorders effectively for optimized retail operations.

Why it is important

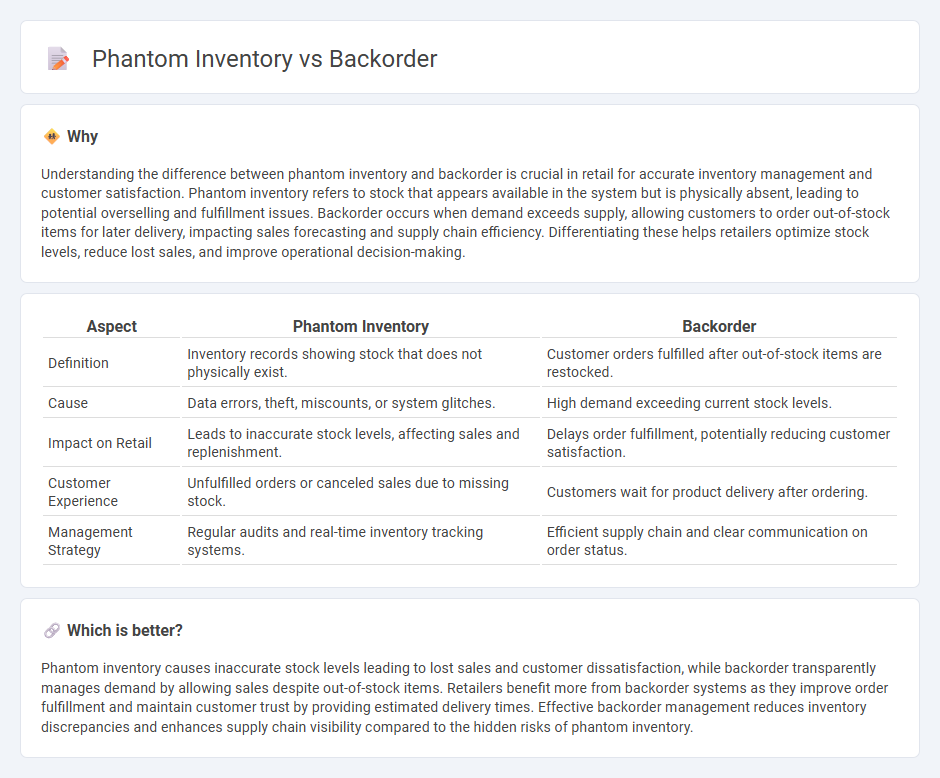

Understanding the difference between phantom inventory and backorder is crucial in retail for accurate inventory management and customer satisfaction. Phantom inventory refers to stock that appears available in the system but is physically absent, leading to potential overselling and fulfillment issues. Backorder occurs when demand exceeds supply, allowing customers to order out-of-stock items for later delivery, impacting sales forecasting and supply chain efficiency. Differentiating these helps retailers optimize stock levels, reduce lost sales, and improve operational decision-making.

Comparison Table

| Aspect | Phantom Inventory | Backorder |

|---|---|---|

| Definition | Inventory records showing stock that does not physically exist. | Customer orders fulfilled after out-of-stock items are restocked. |

| Cause | Data errors, theft, miscounts, or system glitches. | High demand exceeding current stock levels. |

| Impact on Retail | Leads to inaccurate stock levels, affecting sales and replenishment. | Delays order fulfillment, potentially reducing customer satisfaction. |

| Customer Experience | Unfulfilled orders or canceled sales due to missing stock. | Customers wait for product delivery after ordering. |

| Management Strategy | Regular audits and real-time inventory tracking systems. | Efficient supply chain and clear communication on order status. |

Which is better?

Phantom inventory causes inaccurate stock levels leading to lost sales and customer dissatisfaction, while backorder transparently manages demand by allowing sales despite out-of-stock items. Retailers benefit more from backorder systems as they improve order fulfillment and maintain customer trust by providing estimated delivery times. Effective backorder management reduces inventory discrepancies and enhances supply chain visibility compared to the hidden risks of phantom inventory.

Connection

Phantom inventory occurs when inventory data inaccurately shows stock availability, leading to discrepancies during order fulfillment. Backorders result when customers place orders for out-of-stock items, often triggered by phantom inventory misrepresentations. Accurate inventory management systems reduce phantom inventory, minimizing backorders and improving retail supply chain efficiency.

Key Terms

Stockouts

Backorder inventory represents customer orders awaiting fulfillment due to temporary stockouts, whereas phantom inventory reflects inaccuracies in recorded stock levels, often causing false stockouts. Understanding the distinction helps businesses improve inventory accuracy and reduce lost sales by addressing real supply shortages and data errors separately. Explore more strategies to manage stockouts and optimize inventory performance.

Inventory Accuracy

Backorder inventory represents products that are out of stock but can be fulfilled once replenished, while phantom inventory refers to discrepancies in stock records showing items as available when they are not physically present. Accurate inventory management minimizes costly stockouts and excess holding, ensuring reliable order fulfillment and customer satisfaction. Explore how optimizing inventory accuracy can enhance operational efficiency and reduce financial risks.

Order Fulfillment

Backorder inventory occurs when customer orders exceed available stock, leading to delayed fulfillment until restocking, while phantom inventory refers to stock that appears available in the system but is not physically present, causing fulfillment errors. Efficient order fulfillment requires accurate inventory tracking systems and real-time data integration to minimize backorders and prevent phantom inventory discrepancies. Explore advanced inventory management solutions to optimize order accuracy and customer satisfaction.

Source and External Links

What is Backorder? Definition, Challenge, Tips & Tools - Cin7 - A backorder is an order that a business promises to fulfill even though the item is not currently in stock, with the customer agreeing to wait until it becomes available.

Backorder: Meaning, Causes, Minimizing & Managing Tips - ShipBob - An item on backorder is out of stock but is expected to be restocked and shipped by a specific future date, unlike "out of stock" which has no guaranteed return date.

Backorder: Definition, How to Manage, and vs. Out-of-Stock - NetSuite - A backorder occurs when a company accepts an order for a product not currently in inventory but still in production or expected from a supplier, with fulfillment planned once stock is replenished.

dowidth.com

dowidth.com