Moonshot thinking focuses on ambitious, breakthrough goals that drive radical innovation by embracing risk and exploring uncharted territory, while Lean Management emphasizes continuous improvement, waste reduction, and efficiency within existing processes. Companies leveraging moonshot thinking aim to create disruptive solutions with transformative impact, whereas Lean Management optimizes operational performance through iterative adjustments. Discover more about how these contrasting approaches can shape your organization's success.

Why it is important

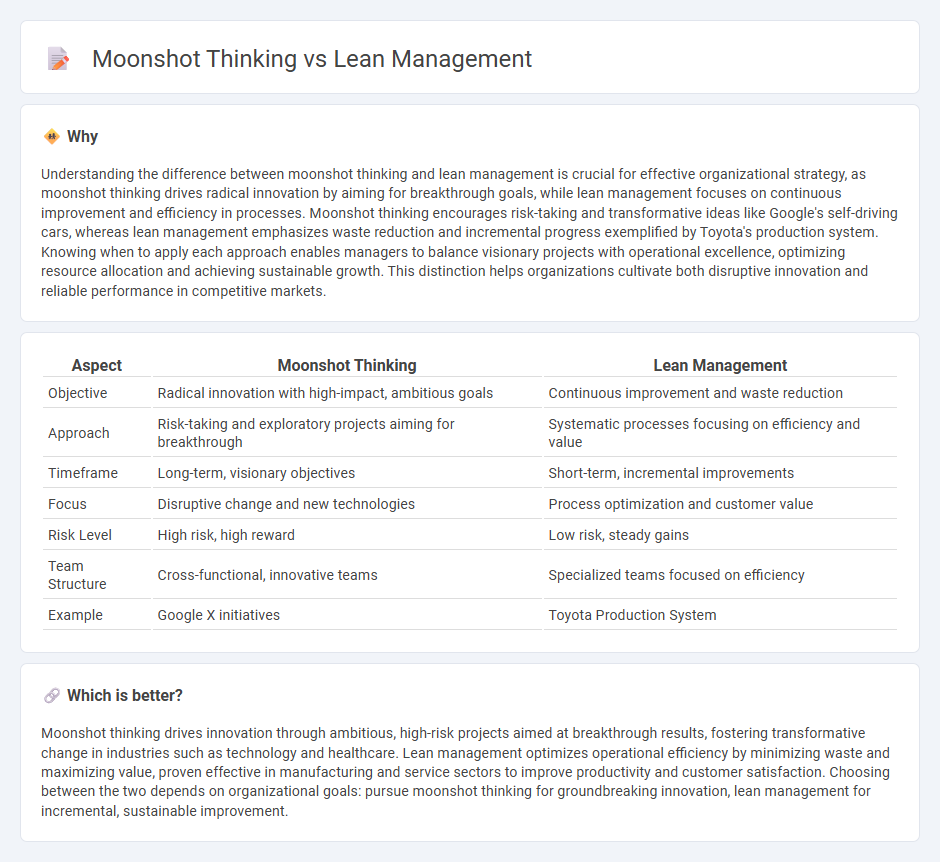

Understanding the difference between moonshot thinking and lean management is crucial for effective organizational strategy, as moonshot thinking drives radical innovation by aiming for breakthrough goals, while lean management focuses on continuous improvement and efficiency in processes. Moonshot thinking encourages risk-taking and transformative ideas like Google's self-driving cars, whereas lean management emphasizes waste reduction and incremental progress exemplified by Toyota's production system. Knowing when to apply each approach enables managers to balance visionary projects with operational excellence, optimizing resource allocation and achieving sustainable growth. This distinction helps organizations cultivate both disruptive innovation and reliable performance in competitive markets.

Comparison Table

| Aspect | Moonshot Thinking | Lean Management |

|---|---|---|

| Objective | Radical innovation with high-impact, ambitious goals | Continuous improvement and waste reduction |

| Approach | Risk-taking and exploratory projects aiming for breakthrough | Systematic processes focusing on efficiency and value |

| Timeframe | Long-term, visionary objectives | Short-term, incremental improvements |

| Focus | Disruptive change and new technologies | Process optimization and customer value |

| Risk Level | High risk, high reward | Low risk, steady gains |

| Team Structure | Cross-functional, innovative teams | Specialized teams focused on efficiency |

| Example | Google X initiatives | Toyota Production System |

Which is better?

Moonshot thinking drives innovation through ambitious, high-risk projects aimed at breakthrough results, fostering transformative change in industries such as technology and healthcare. Lean management optimizes operational efficiency by minimizing waste and maximizing value, proven effective in manufacturing and service sectors to improve productivity and customer satisfaction. Choosing between the two depends on organizational goals: pursue moonshot thinking for groundbreaking innovation, lean management for incremental, sustainable improvement.

Connection

Moonshot thinking drives radical innovation by encouraging ambitious, groundbreaking goals, while lean management focuses on efficiency and minimizing waste in processes. Integrating moonshot thinking with lean management enables organizations to pursue disruptive breakthroughs without sacrificing operational discipline or resource allocation. This synergy accelerates transformative projects by combining visionary creativity with systematic, iterative improvement.

Key Terms

**Lean Management:**

Lean Management emphasizes continuous improvement by eliminating waste, optimizing workflows, and maximizing value for customers through iterative processes and data-driven decision making. It fosters a culture of efficiency and adaptability, often applied in manufacturing, software development, and service industries to enhance productivity and reduce costs. Explore how Lean Management can transform operational performance and drive sustainable growth.

Continuous Improvement (Kaizen)

Lean management emphasizes continuous improvement through Kaizen, aiming to eliminate waste and optimize processes incrementally. Moonshot thinking encourages bold, innovative breakthroughs by setting ambitious, long-term goals that challenge conventional limits. Explore how integrating both approaches can drive transformative and sustainable growth.

Waste Reduction

Lean management emphasizes continuous waste reduction by streamlining processes and eliminating inefficiencies, resulting in improved productivity and cost savings. Moonshot thinking targets ambitious, high-impact innovations that can reshape entire industries, although its approach may involve higher risks and resource investment. Explore how these contrasting methodologies can complement each other to drive both efficiency and breakthrough innovation.

Source and External Links

What is Lean Management? | Definition from TechTarget - Lean management is a continuous improvement approach focused on creating customer value by eliminating waste and optimizing workflow, rooted in the Toyota production system.

What is a Lean Management System? - Lean Enterprise Academy - A lean management system involves line managers taking responsibility for both performance and improvement simultaneously, emphasizing problem-solving at all organizational levels.

Definition, tools and advantages of Lean Management - Lean management optimizes processes by minimizing non-value-added activities, creating smooth workflows, and encouraging continuous improvement through techniques like daily team meetings.

dowidth.com

dowidth.com