Due diligence deep dive evaluates risks, financials, and compliance to ensure informed decisions during mergers and acquisitions, providing a detailed assessment of a target company. Process optimization focuses on improving operational efficiency, reducing costs, and enhancing productivity through analysis and redesign of business processes. Explore the key differences and benefits of each approach to elevate your consulting strategy.

Why it is important

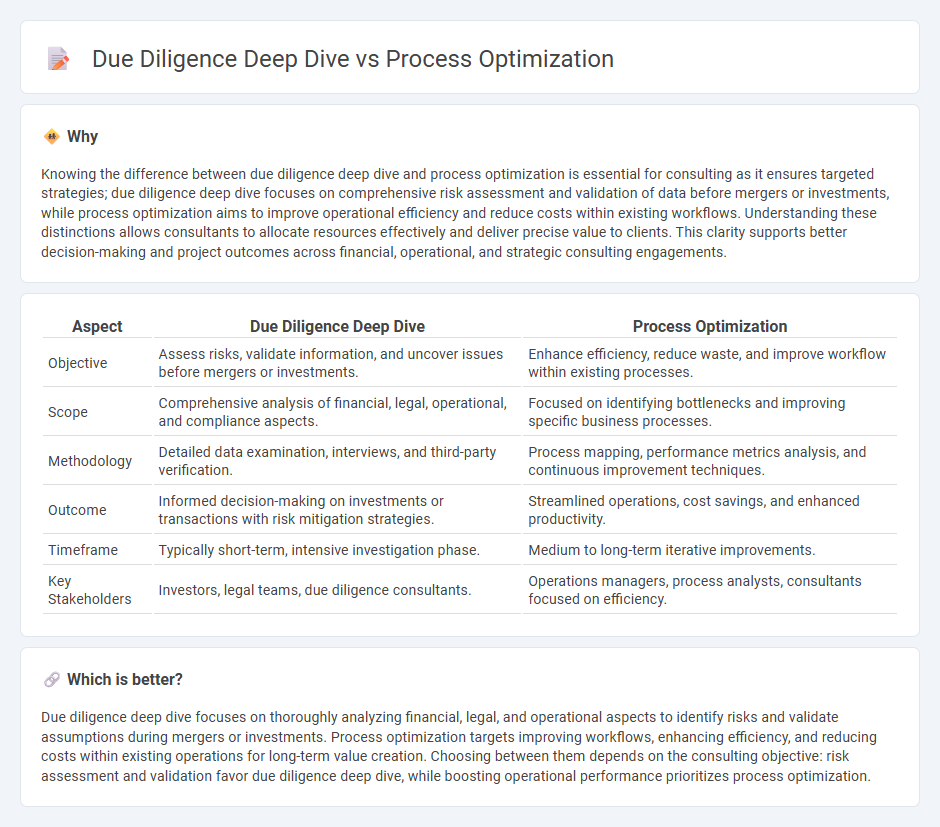

Knowing the difference between due diligence deep dive and process optimization is essential for consulting as it ensures targeted strategies; due diligence deep dive focuses on comprehensive risk assessment and validation of data before mergers or investments, while process optimization aims to improve operational efficiency and reduce costs within existing workflows. Understanding these distinctions allows consultants to allocate resources effectively and deliver precise value to clients. This clarity supports better decision-making and project outcomes across financial, operational, and strategic consulting engagements.

Comparison Table

| Aspect | Due Diligence Deep Dive | Process Optimization |

|---|---|---|

| Objective | Assess risks, validate information, and uncover issues before mergers or investments. | Enhance efficiency, reduce waste, and improve workflow within existing processes. |

| Scope | Comprehensive analysis of financial, legal, operational, and compliance aspects. | Focused on identifying bottlenecks and improving specific business processes. |

| Methodology | Detailed data examination, interviews, and third-party verification. | Process mapping, performance metrics analysis, and continuous improvement techniques. |

| Outcome | Informed decision-making on investments or transactions with risk mitigation strategies. | Streamlined operations, cost savings, and enhanced productivity. |

| Timeframe | Typically short-term, intensive investigation phase. | Medium to long-term iterative improvements. |

| Key Stakeholders | Investors, legal teams, due diligence consultants. | Operations managers, process analysts, consultants focused on efficiency. |

Which is better?

Due diligence deep dive focuses on thoroughly analyzing financial, legal, and operational aspects to identify risks and validate assumptions during mergers or investments. Process optimization targets improving workflows, enhancing efficiency, and reducing costs within existing operations for long-term value creation. Choosing between them depends on the consulting objective: risk assessment and validation favor due diligence deep dive, while boosting operational performance prioritizes process optimization.

Connection

Due diligence deep dive involves thoroughly examining a company's financial, operational, and strategic aspects to identify risks and opportunities, providing critical insights for advising clients. Process optimization leverages these insights to streamline workflows, reduce inefficiencies, and enhance overall performance, ensuring that recommendations align with the organization's goals and compliance requirements. The connection lies in using detailed due diligence findings as a foundation for designing targeted process improvements that drive sustainable growth and value creation in consulting engagements.

Key Terms

**Process Optimization:**

Process optimization involves continuously refining workflows to enhance efficiency, reduce costs, and improve overall productivity across business operations. Techniques such as Lean Six Sigma, automation, and data analytics play critical roles in identifying bottlenecks and streamlining processes. Explore comprehensive strategies and best practices for driving sustainable process improvements in your organization.

Lean Six Sigma

Lean Six Sigma enhances process optimization by integrating Lean principles that reduce waste with Six Sigma's focus on minimizing variability and defects, driving measurable improvements in efficiency and quality. Due diligence in this context involves systematically assessing operational workflows, identifying bottlenecks, and verifying compliance with performance standards to ensure informed decision-making and risk mitigation. Explore comprehensive insights on applying Lean Six Sigma for effective process optimization and thorough due diligence.

Bottleneck Analysis

Bottleneck analysis plays a crucial role in both process optimization and due diligence by identifying constraints that limit system performance or project viability. In process optimization, bottleneck analysis enhances operational efficiency by targeting the slowest workflow stages, thereby increasing throughput and reducing cycle time. Explore our comprehensive insights on bottleneck analysis to unlock its full impact on optimizing processes and assessing business risks.

Source and External Links

Process optimization - Wikipedia - Process optimization is the discipline of adjusting a process to make the best or most effective use of specified parameters, aiming to minimize cost and maximize throughput or efficiency by focusing on equipment, operating procedures, and control systems without violating constraints.

Process Optimization: Increasing Business Efficiency - SixSigma.us - Process optimization systematically refines business operations by identifying high-impact processes, analyzing current performance, and setting measurable goals such as reducing cycle time or costs to improve efficiency and effectiveness.

Process Optimization Explained - Methods, Benefits & Tools - Process optimization involves analyzing and improving business workflows using methods like process mapping, process mining, root-cause analysis, and methodologies such as DMAIC, Kaizen, and Six Sigma to maximize efficiency and quality.

dowidth.com

dowidth.com