Digital twin simulation creates a virtual replica of physical systems, allowing real-time monitoring and scenario testing to optimize performance and reduce downtime. Predictive analytics uses historical data and machine learning algorithms to forecast future trends and identify potential issues before they occur. Discover how integrating these technologies can enhance business insights and operational efficiency.

Why it is important

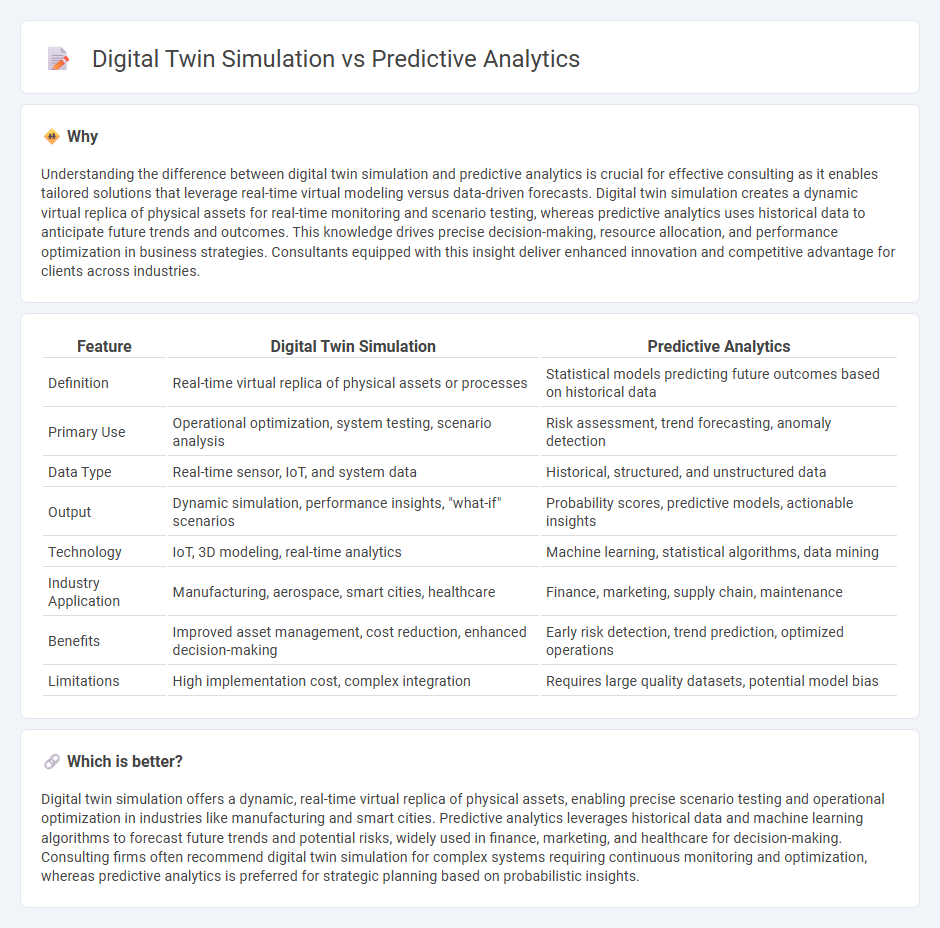

Understanding the difference between digital twin simulation and predictive analytics is crucial for effective consulting as it enables tailored solutions that leverage real-time virtual modeling versus data-driven forecasts. Digital twin simulation creates a dynamic virtual replica of physical assets for real-time monitoring and scenario testing, whereas predictive analytics uses historical data to anticipate future trends and outcomes. This knowledge drives precise decision-making, resource allocation, and performance optimization in business strategies. Consultants equipped with this insight deliver enhanced innovation and competitive advantage for clients across industries.

Comparison Table

| Feature | Digital Twin Simulation | Predictive Analytics |

|---|---|---|

| Definition | Real-time virtual replica of physical assets or processes | Statistical models predicting future outcomes based on historical data |

| Primary Use | Operational optimization, system testing, scenario analysis | Risk assessment, trend forecasting, anomaly detection |

| Data Type | Real-time sensor, IoT, and system data | Historical, structured, and unstructured data |

| Output | Dynamic simulation, performance insights, "what-if" scenarios | Probability scores, predictive models, actionable insights |

| Technology | IoT, 3D modeling, real-time analytics | Machine learning, statistical algorithms, data mining |

| Industry Application | Manufacturing, aerospace, smart cities, healthcare | Finance, marketing, supply chain, maintenance |

| Benefits | Improved asset management, cost reduction, enhanced decision-making | Early risk detection, trend prediction, optimized operations |

| Limitations | High implementation cost, complex integration | Requires large quality datasets, potential model bias |

Which is better?

Digital twin simulation offers a dynamic, real-time virtual replica of physical assets, enabling precise scenario testing and operational optimization in industries like manufacturing and smart cities. Predictive analytics leverages historical data and machine learning algorithms to forecast future trends and potential risks, widely used in finance, marketing, and healthcare for decision-making. Consulting firms often recommend digital twin simulation for complex systems requiring continuous monitoring and optimization, whereas predictive analytics is preferred for strategic planning based on probabilistic insights.

Connection

Digital twin simulation leverages real-time data to create virtual replicas of physical assets, enabling predictive analytics to forecast future performance and potential failures. By integrating sensor data and machine learning algorithms, predictive analytics enhances the accuracy of digital twin simulations, facilitating proactive decision-making in consulting. This synergy optimizes operational efficiency and reduces risk by providing actionable insights derived from simulated scenarios and data-driven predictions.

Key Terms

Data Modeling

Predictive analytics leverages historical and real-time data through advanced statistical models and machine learning algorithms to forecast future outcomes, while digital twin simulation creates a dynamic, virtual replica of physical assets or processes for scenario testing and optimization. Data modeling in predictive analytics centers on identifying patterns and relationships within datasets to generate accurate predictions, whereas digital twin simulation requires detailed, physics-based models integrated with sensor data to mirror real-world behaviors precisely. Explore the distinctions in data modeling techniques to understand how each approach enhances decision-making and operational efficiency.

Real-time Simulation

Predictive analytics leverages historical data to forecast future outcomes, enhancing decision-making processes by identifying trends and potential risks. Digital twin simulation creates a real-time virtual model of physical assets, enabling dynamic interaction and instant updates to reflect current operational conditions. Explore how integrating predictive analytics with real-time digital twin simulations can drive superior accuracy and efficiency in smart manufacturing and IoT applications.

Scenario Forecasting

Predictive analytics utilizes historical data and machine learning algorithms to forecast future scenarios with high accuracy, enabling businesses to anticipate trends and make informed decisions. Digital twin simulation creates a virtual replica of physical assets or systems, providing real-time scenario forecasting by simulating various operational conditions and their potential impacts. Explore deeper insights into how combining predictive analytics and digital twin simulation enhances scenario forecasting accuracy and decision-making efficiency.

Source and External Links

What is Predictive Analytics? | IBM - Predictive analytics uses historical data combined with statistical modeling, data mining, and machine learning to identify patterns and predict future outcomes, often employing classification, clustering, and time series models to assess risks and opportunities.

What is predictive analytics and how does it work? | Google Cloud - Predictive analytics forecasts future outcomes using data analysis, machine learning, AI, and statistical models, typically through classification and regression models to categorize data or predict continuous variables.

A Guide To Predictive Analytics | Tableau - Predictive analytics determines the likelihood of future events by utilizing data mining, statistics, AI, and machine learning to interpret historical data and identify upcoming risks and opportunities for proactive decision-making.

dowidth.com

dowidth.com