Supply chain traceability consulting specializes in tracking product movement and origin across the supply chain, enhancing transparency and compliance with regulations such as FDA and EU standards. Inventory management consulting focuses on optimizing stock levels, reducing carrying costs, and improving order fulfillment efficiency through techniques like just-in-time inventory and demand forecasting. Explore the key differences and benefits of each consulting service to determine the best fit for your business needs.

Why it is important

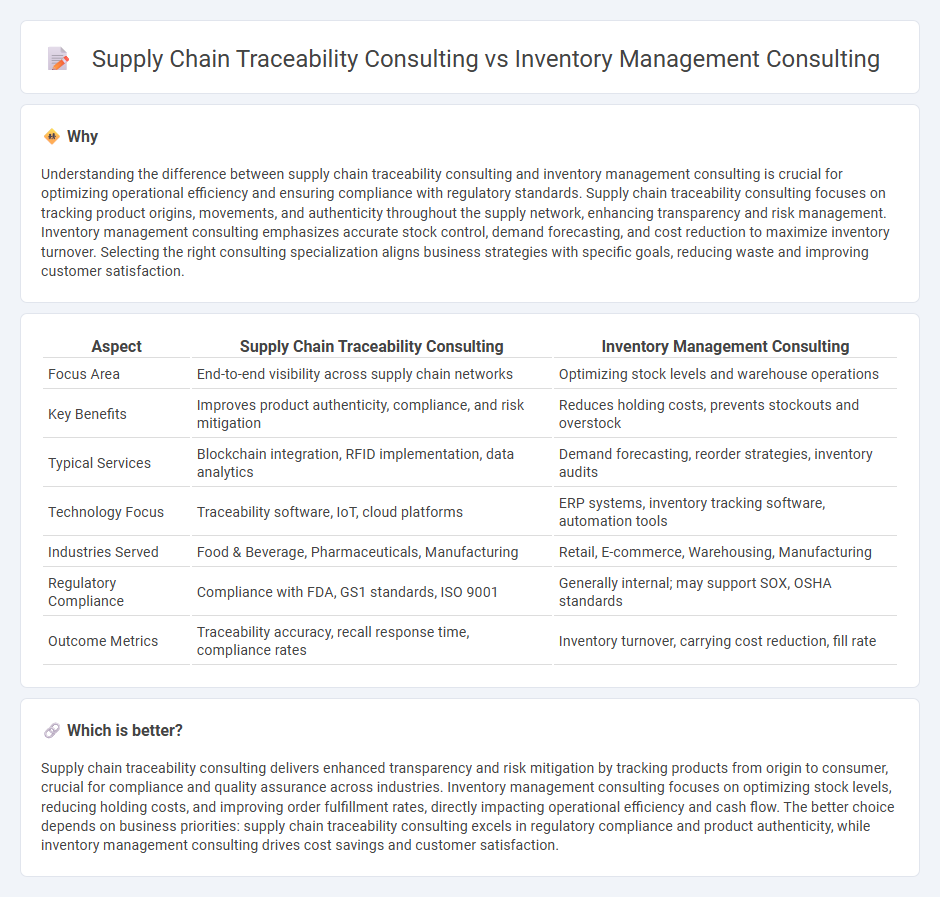

Understanding the difference between supply chain traceability consulting and inventory management consulting is crucial for optimizing operational efficiency and ensuring compliance with regulatory standards. Supply chain traceability consulting focuses on tracking product origins, movements, and authenticity throughout the supply network, enhancing transparency and risk management. Inventory management consulting emphasizes accurate stock control, demand forecasting, and cost reduction to maximize inventory turnover. Selecting the right consulting specialization aligns business strategies with specific goals, reducing waste and improving customer satisfaction.

Comparison Table

| Aspect | Supply Chain Traceability Consulting | Inventory Management Consulting |

|---|---|---|

| Focus Area | End-to-end visibility across supply chain networks | Optimizing stock levels and warehouse operations |

| Key Benefits | Improves product authenticity, compliance, and risk mitigation | Reduces holding costs, prevents stockouts and overstock |

| Typical Services | Blockchain integration, RFID implementation, data analytics | Demand forecasting, reorder strategies, inventory audits |

| Technology Focus | Traceability software, IoT, cloud platforms | ERP systems, inventory tracking software, automation tools |

| Industries Served | Food & Beverage, Pharmaceuticals, Manufacturing | Retail, E-commerce, Warehousing, Manufacturing |

| Regulatory Compliance | Compliance with FDA, GS1 standards, ISO 9001 | Generally internal; may support SOX, OSHA standards |

| Outcome Metrics | Traceability accuracy, recall response time, compliance rates | Inventory turnover, carrying cost reduction, fill rate |

Which is better?

Supply chain traceability consulting delivers enhanced transparency and risk mitigation by tracking products from origin to consumer, crucial for compliance and quality assurance across industries. Inventory management consulting focuses on optimizing stock levels, reducing holding costs, and improving order fulfillment rates, directly impacting operational efficiency and cash flow. The better choice depends on business priorities: supply chain traceability consulting excels in regulatory compliance and product authenticity, while inventory management consulting drives cost savings and customer satisfaction.

Connection

Supply chain traceability consulting and inventory management consulting are interconnected through their focus on enhancing visibility and control within supply chain operations. Traceability consulting ensures accurate tracking of products from origin to consumer, enabling real-time data flow that informs inventory management decisions. Effective integration of these consulting services leads to optimized stock levels, reduced waste, and improved demand forecasting accuracy.

Key Terms

Inventory management consulting:

Inventory management consulting streams focus on optimizing stock levels, reducing carrying costs, and improving demand forecasting accuracy to enhance overall operational efficiency. Consultants analyze inventory turnover rates, safety stock thresholds, and reorder points using advanced analytics and ERP integration for tailored solutions. Discover how inventory management consulting can transform your business by exploring expert strategies and tools.

Stock Optimization

Inventory management consulting specializes in stock optimization by analyzing demand patterns, reducing excess inventory, and improving reorder processes to ensure optimal stock levels that minimize holding costs and prevent stockouts. Supply chain traceability consulting enhances visibility across the supply chain, tracking product movement and provenance, which indirectly supports inventory decisions through real-time data but is less focused on direct stock optimization. Explore more to understand how each consulting approach can uniquely improve your inventory management strategies.

Demand Forecasting

Inventory management consulting centers on optimizing demand forecasting through advanced analytics and real-time data integration to reduce stockouts and overstock scenarios. Supply chain traceability consulting enhances demand forecasting by improving transparency and tracking product movement, enabling more accurate and responsive inventory decisions. Explore how tailored consulting services can transform your demand forecasting and inventory strategies for better operational efficiency.

Source and External Links

Inventory Consulting Services - Expert inventory management consulting by Jon and Matt Schreibfeder offering detailed inventory situation analysis, operations planning, and customized solutions to improve product availability and profitability across various industries.

Inventory Management Optimization | Altemir Consulting - Specialized consulting focused on optimizing manufacturers' inventory to increase fill rates over 99%, reduce inventory by 25-50%, and implement lean inventory techniques like kanbans and EOQs.

Inventory Management Consulting Services | RTG Solutions Group - Provides data-driven, tailored inventory consulting to solve stock-outs, over-stock issues, vendor management, and supply chain disruption risks, boosting efficiency and profits.

dowidth.com

dowidth.com