Digital twin simulation enables real-time virtual replication of physical assets or processes, facilitating predictive analysis and performance optimization. Digital thread integrates data across the entire product lifecycle, providing a continuous, unbroken flow of information for enhanced decision-making and traceability. Explore how combining digital twin simulation with digital thread strategies can revolutionize your consulting outcomes.

Why it is important

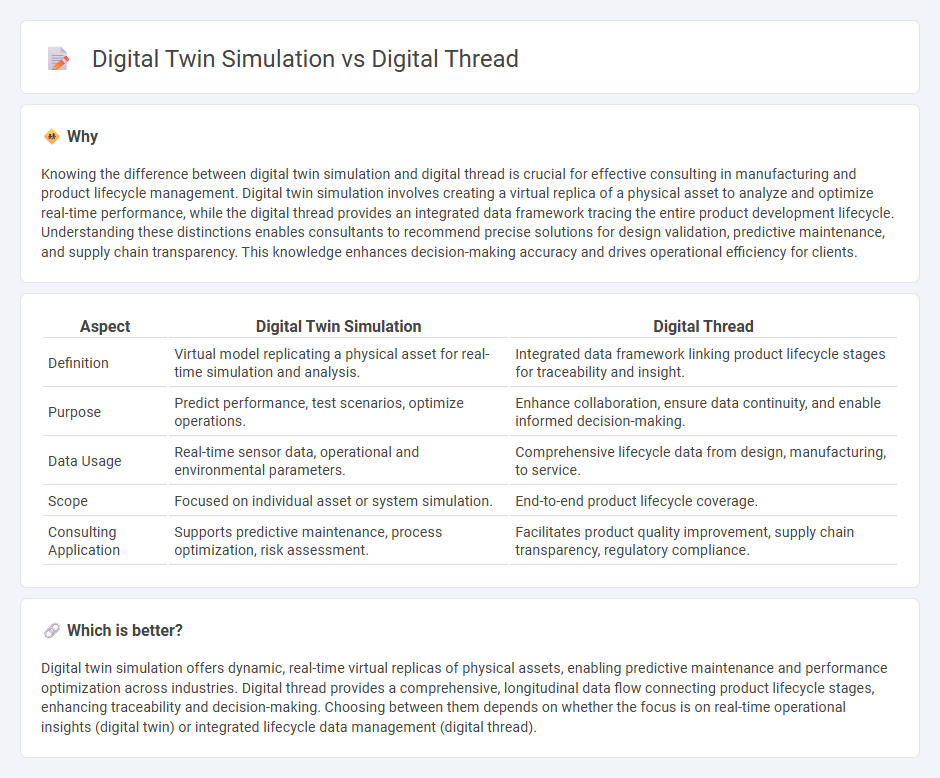

Knowing the difference between digital twin simulation and digital thread is crucial for effective consulting in manufacturing and product lifecycle management. Digital twin simulation involves creating a virtual replica of a physical asset to analyze and optimize real-time performance, while the digital thread provides an integrated data framework tracing the entire product development lifecycle. Understanding these distinctions enables consultants to recommend precise solutions for design validation, predictive maintenance, and supply chain transparency. This knowledge enhances decision-making accuracy and drives operational efficiency for clients.

Comparison Table

| Aspect | Digital Twin Simulation | Digital Thread |

|---|---|---|

| Definition | Virtual model replicating a physical asset for real-time simulation and analysis. | Integrated data framework linking product lifecycle stages for traceability and insight. |

| Purpose | Predict performance, test scenarios, optimize operations. | Enhance collaboration, ensure data continuity, and enable informed decision-making. |

| Data Usage | Real-time sensor data, operational and environmental parameters. | Comprehensive lifecycle data from design, manufacturing, to service. |

| Scope | Focused on individual asset or system simulation. | End-to-end product lifecycle coverage. |

| Consulting Application | Supports predictive maintenance, process optimization, risk assessment. | Facilitates product quality improvement, supply chain transparency, regulatory compliance. |

Which is better?

Digital twin simulation offers dynamic, real-time virtual replicas of physical assets, enabling predictive maintenance and performance optimization across industries. Digital thread provides a comprehensive, longitudinal data flow connecting product lifecycle stages, enhancing traceability and decision-making. Choosing between them depends on whether the focus is on real-time operational insights (digital twin) or integrated lifecycle data management (digital thread).

Connection

Digital twin simulation and Digital Thread are interconnected technologies that enhance product lifecycle management by enabling real-time data integration and continuous feedback loops. The Digital Thread provides a comprehensive data framework linking design, production, and operational phases, while digital twin simulation uses this data to create virtual models for predictive analysis and optimization. Together, they drive informed decision-making, reduce development costs, and improve product quality across the entire value chain.

Key Terms

Data Integration

Digital thread integrates data across the entire product lifecycle, enabling seamless information flow from design to manufacturing and maintenance, while digital twin simulation creates a virtual replica of a physical asset to analyze performance and predict issues using real-time data. The digital thread emphasizes comprehensive data integration and traceability across systems and processes, supporting informed decision-making and continuous improvement. Explore deeper insights into how these technologies complement each other in enhancing operational efficiency and innovation.

Real-time Analytics

Digital thread integrates real-time analytics by continuously linking data from design, manufacturing, and lifecycle processes, enabling holistic visibility and proactive decision-making across the product lifecycle. Digital twin simulation leverages real-time analytics to create dynamic virtual models that reflect current operational conditions, allowing for predictive maintenance and performance optimization. Explore how real-time analytics enhances both digital thread and digital twin applications for improved manufacturing intelligence.

Lifecycle Management

Digital thread integrates data, processes, and systems to create a comprehensive view of a product's lifecycle, enabling seamless information flow from design to disposal. Digital twin simulation uses real-time data to replicate and analyze the physical asset's performance, supporting predictive maintenance and operational optimization. Explore how combining digital thread and digital twin can revolutionize lifecycle management for enhanced product innovation and efficiency.

Source and External Links

Digital thread - Wikipedia - A digital thread is a data-driven architecture linking data from all stages and systems throughout a product's lifecycle, enabling real-time decision making and integration across distributed manufacturing systems.

Definition of Digital Thread - Digital Twin Consortium - The digital thread is a bidirectional, trustworthy information system connecting multiple lifecycle stages and dimensions to ensure seamless data exchange and interoperability, crucial for enabling digital twin capabilities and real-time insights.

A digital thread What it is and why you need it - AVEVA - A digital thread represents the continuous digital flow of data chained between connected systems and users, ensuring everyone in an organization accesses the same reliable and timely information to make confident decisions.

dowidth.com

dowidth.com