Digital twin simulation creates a virtual replica of physical assets or systems for real-time monitoring and predictive analysis, enhancing operational efficiency in industries like manufacturing and urban planning. Business Process Modeling focuses on representing and analyzing organizational workflows to optimize processes and improve decision-making within businesses. Explore the distinct advantages of digital twin simulation and business process modeling to determine the best strategy for your organization's needs.

Why it is important

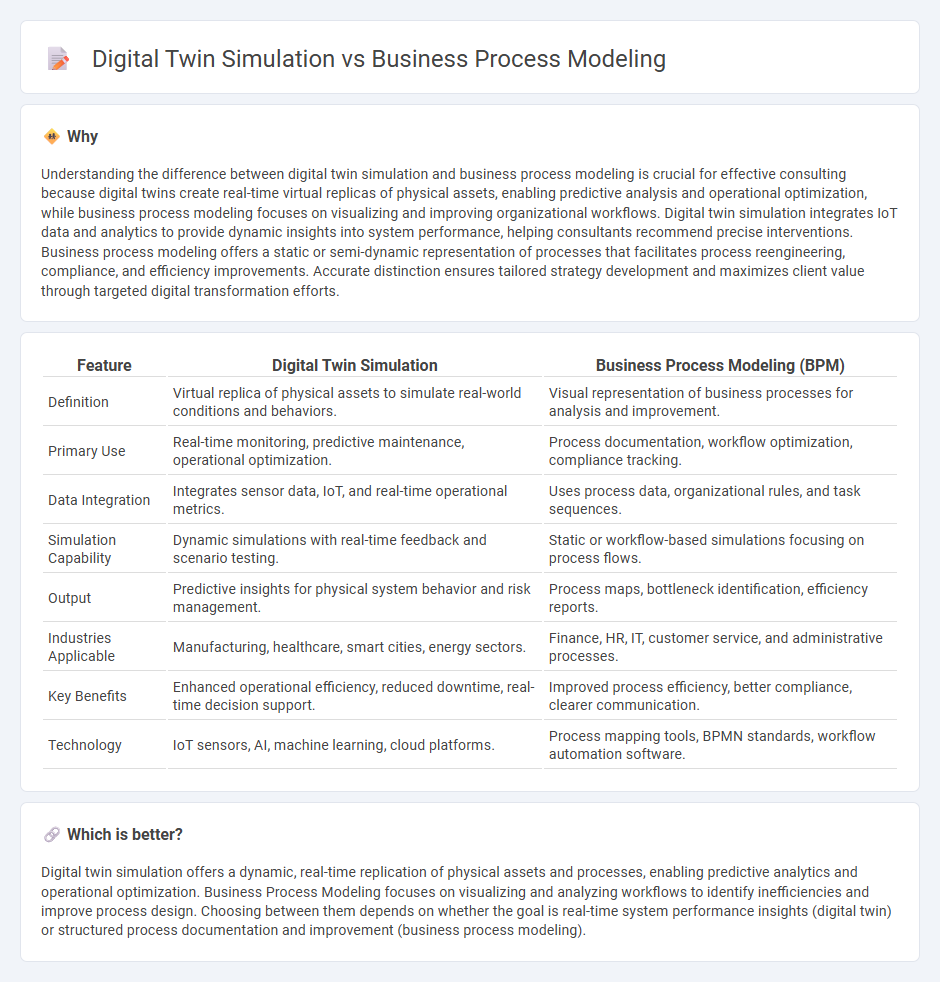

Understanding the difference between digital twin simulation and business process modeling is crucial for effective consulting because digital twins create real-time virtual replicas of physical assets, enabling predictive analysis and operational optimization, while business process modeling focuses on visualizing and improving organizational workflows. Digital twin simulation integrates IoT data and analytics to provide dynamic insights into system performance, helping consultants recommend precise interventions. Business process modeling offers a static or semi-dynamic representation of processes that facilitates process reengineering, compliance, and efficiency improvements. Accurate distinction ensures tailored strategy development and maximizes client value through targeted digital transformation efforts.

Comparison Table

| Feature | Digital Twin Simulation | Business Process Modeling (BPM) |

|---|---|---|

| Definition | Virtual replica of physical assets to simulate real-world conditions and behaviors. | Visual representation of business processes for analysis and improvement. |

| Primary Use | Real-time monitoring, predictive maintenance, operational optimization. | Process documentation, workflow optimization, compliance tracking. |

| Data Integration | Integrates sensor data, IoT, and real-time operational metrics. | Uses process data, organizational rules, and task sequences. |

| Simulation Capability | Dynamic simulations with real-time feedback and scenario testing. | Static or workflow-based simulations focusing on process flows. |

| Output | Predictive insights for physical system behavior and risk management. | Process maps, bottleneck identification, efficiency reports. |

| Industries Applicable | Manufacturing, healthcare, smart cities, energy sectors. | Finance, HR, IT, customer service, and administrative processes. |

| Key Benefits | Enhanced operational efficiency, reduced downtime, real-time decision support. | Improved process efficiency, better compliance, clearer communication. |

| Technology | IoT sensors, AI, machine learning, cloud platforms. | Process mapping tools, BPMN standards, workflow automation software. |

Which is better?

Digital twin simulation offers a dynamic, real-time replication of physical assets and processes, enabling predictive analytics and operational optimization. Business Process Modeling focuses on visualizing and analyzing workflows to identify inefficiencies and improve process design. Choosing between them depends on whether the goal is real-time system performance insights (digital twin) or structured process documentation and improvement (business process modeling).

Connection

Digital twin simulation and Business Process Modeling (BPM) are interconnected through their ability to create dynamic, data-driven representations of organizational operations. Digital twin simulation uses real-time data to mirror physical processes, enhancing BPM's static workflows with predictive analytics and scenario testing. This integration enables consultants to optimize processes, reduce risks, and improve decision-making by visualizing and experimenting with operational changes before implementation.

Key Terms

Process Mapping

Business process modeling centers on visualizing workflows and tasks to enhance efficiency and identify bottlenecks within an organization, using tools like BPMN for detailed process mapping. Digital twin simulation creates a dynamic, real-time virtual replica of physical processes or systems, allowing for predictive analysis and performance optimization through continuous data integration. Explore how integrating process mapping with digital twin technology can revolutionize operational insights and decision-making.

Real-time Data Integration

Business Process Modeling (BPM) provides structured visualizations of workflows to optimize operations, while Digital Twin Simulation replicates physical processes or systems using real-time data integration for dynamic analysis and decision-making. Real-time data integration in Digital Twin Simulations enables continuous monitoring and predictive adjustments, enhancing responsiveness beyond static process models found in BPM. Explore the transformative impact of real-time data in bridging BPM and Digital Twin Simulations.

Scenario Analysis

Business process modeling provides a structured framework to map, analyze, and optimize workflows, enabling organizations to identify bottlenecks and improve efficiency through scenario analysis. Digital twin simulation creates dynamic, real-time virtual replicas of physical processes, allowing for predictive scenario testing and enhanced decision-making by integrating live data. Explore in-depth how each approach leverages scenario analysis to transform operational strategies and achieve superior business outcomes.

Source and External Links

What is Process Modeling? - Process modeling creates data-driven visual representations of key business processes to help organizations understand, optimize workflows, document activities, identify problems, and automate processes effectively.

Business process modeling - Business process modeling captures and visually represents enterprise processes to analyze current workflows, facilitate redesign or optimization, and align activities with business goals as a key discipline within Business Process Management.

What is Process Modeling? Definition, Techniques, ... - Process modeling uses techniques like BPMN, UML Activity Diagrams, flowcharting, and swimlane diagrams to create clear, standardized graphical representations of business process flows for better stakeholder understanding and process improvement.

dowidth.com

dowidth.com